In a realm brimming with threads of creativity, I found myself fully immersed within the captivating embrace of a workshop held at the DigitalFUTURES summer work camps in 2021. Here, the essence of construction took on an artistic allure as we sprayed fast-setting polymer materials upon the supple canvas of an inflatable membrane, guided by the movements of robotics. This gathering became a tapestry of exploration, weaving together diverse construction technologies and design software, igniting the sparks of our collective imagination.

Like the stroke of an artist's brush, a handheld 3D scanner breathed life into the air membrane, capturing its essence with a precision that left us in awe. We marveled as the structure's thickness came alive before our eyes, calculated in real-time, transforming our vision into tangible reality. Guided by the versatile prowess of 3D structure software, we embarked on a dance between form and function, meticulously determining the variable section strength of the materials. In this intricate interplay, technology and craftsmanship melded seamlessly, birthing a harmonious fusion that resonated in every corner of our creation.

Embracing the compass of parametric design, we ventured into a realm where possibilities knew no bounds. Here, the visions of each individual became a vibrant thread woven into our collective aspirations. With each step forward, we unraveled the hidden properties of building materials, delving into the delicate nuances of polyurethane density, material composition, and the optimal setting time for our spraying construction. In this quest for mastery, we discovered the artistry concealed within the fabric of our craft.

Within the vibrant realm of the pattern design group, I embarked on a journey of exploration, delving deep into the potential of constructing a spray path through the enchanting lens of parametric approach. As I began my odyssey, crafting digital patterns with precision, my teammates in the construction group diligently filled the expansive membrane room with the breath of life itself. Together, we ventured forth, conducting on-site verifications and keen observations, allowing our designs to flourish and evolve. With every shift in air pressure, the air membrane gracefully transformed, a testament to the dynamic forces at play.

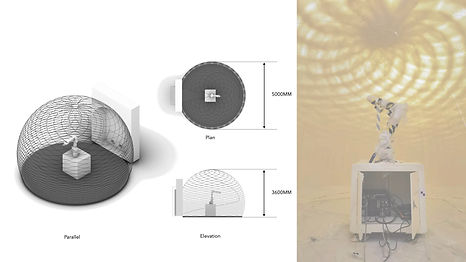

With a keen eye on both structural integrity and aesthetic allure, I present to you the culmination of our collective efforts. Behold, the images below unveil two final patterns, each embodying its own unique essence. The first pattern unveils a sphere, a symbol of unity and harmony, its curves dancing in synchrony with the surrounding environment. The second pattern pays homage to the allure of a water drop, capturing the beauty of nature's delicate creations. In these intricate designs, we find a harmonious marriage of technology and artistry, offering a glimpse into the vast possibilities that lie before us.

After extensive experimentation and curve tension testing using kangaroo simulations, a particular design emerged as the chosen one—a captivating gradient of undulating waves. This carefully curated pattern not only met but surpassed the requirements for the crucial bottom tamping of our air-filled sprayed pavilion.

To ensure the optimal support and stability of the spherical structure, our dedicated team embarked on a spraying process, commencing from the bottom and gradually ascending.

Notably, the bottom section received a significantly thicker application compared to the upper part, a deliberate choice to reinforce the sphere's integrity. Through the strategic implementation of overlapping components, we were able to imbue the structure with added stability, effectively mitigating any undue shape morphing that may arise during the liquid spraying process.

Immersed in the realm of design, our chosen pattern aligns with the precise requirements of the robotic arm's movements. Simultaneously, it orchestrates a symphony of time and temperature, poised to initiate a captivating chemical reaction as the spraying journey unfolds from bottom to top.

This crafted design integrates form and function, ensuring a synchronization with the maneuvers of the robotic arm. It embraces the inherent characteristics of the spraying process, providing the ideal conditions for a delicate chemical dance to transpire. With each stroke from bottom to top, the design allows for an appropriate passage of time and temperature, serving as a catalyst for the desired chemical reactions to blossom and create a fusion of artistry and engineering.

In this convergence of aesthetics and technological precision, we witness the birth of a design that not only fulfills the demands of the robotic arm but also breathes life into a chemical symphony.